Aerospace engineering is a highly specialized field that demands precision, reliability, and safety in every aspect of the design and manufacturing process. Among the most critical components in aerospace manufacturing are the instruments, machines, and devices used to shape, fabricate, and assemble aircraft parts.

The correct aerospace tooling is critical to ensuring efficient and accurate production while maintaining the highest quality standards. Carr Lane Mfg. will explore the key considerations engineers should consider when choosing aerospace tooling.

Understanding Aerospace Tooling

Aerospace tooling refers to the equipment, tools, jigs, fixtures, and molds used in the aerospace industry to fabricate and assemble various aircraft and spacecraft components.

These tools are designed to meet the exacting standards and specifications required by aerospace engineering, often involving cutting-edge technology and materials. Aerospace tooling includes CNC machines, inspection gauges, composite molding forms, assembly jigs, and precision measurement devices.

High-quality tooling is essential for several reasons:

- Precision and accuracy: Parts must be fabricated to exact specifications, reducing the likelihood of misalignments, poor fits, and operational issues.

- Consistency: You must maintain consistent shapes, sizes, and dimensions to reduce variations between parts.

- Safety: Aircraft safety is the most essential element. Flaws or inconsistencies in aircraft components because of subpar tooling can compromise the structural integrity and safety of the aircraft.

- Durability and reliability: Quality tooling ensures that aircraft parts are robust enough to withstand extreme conditions.

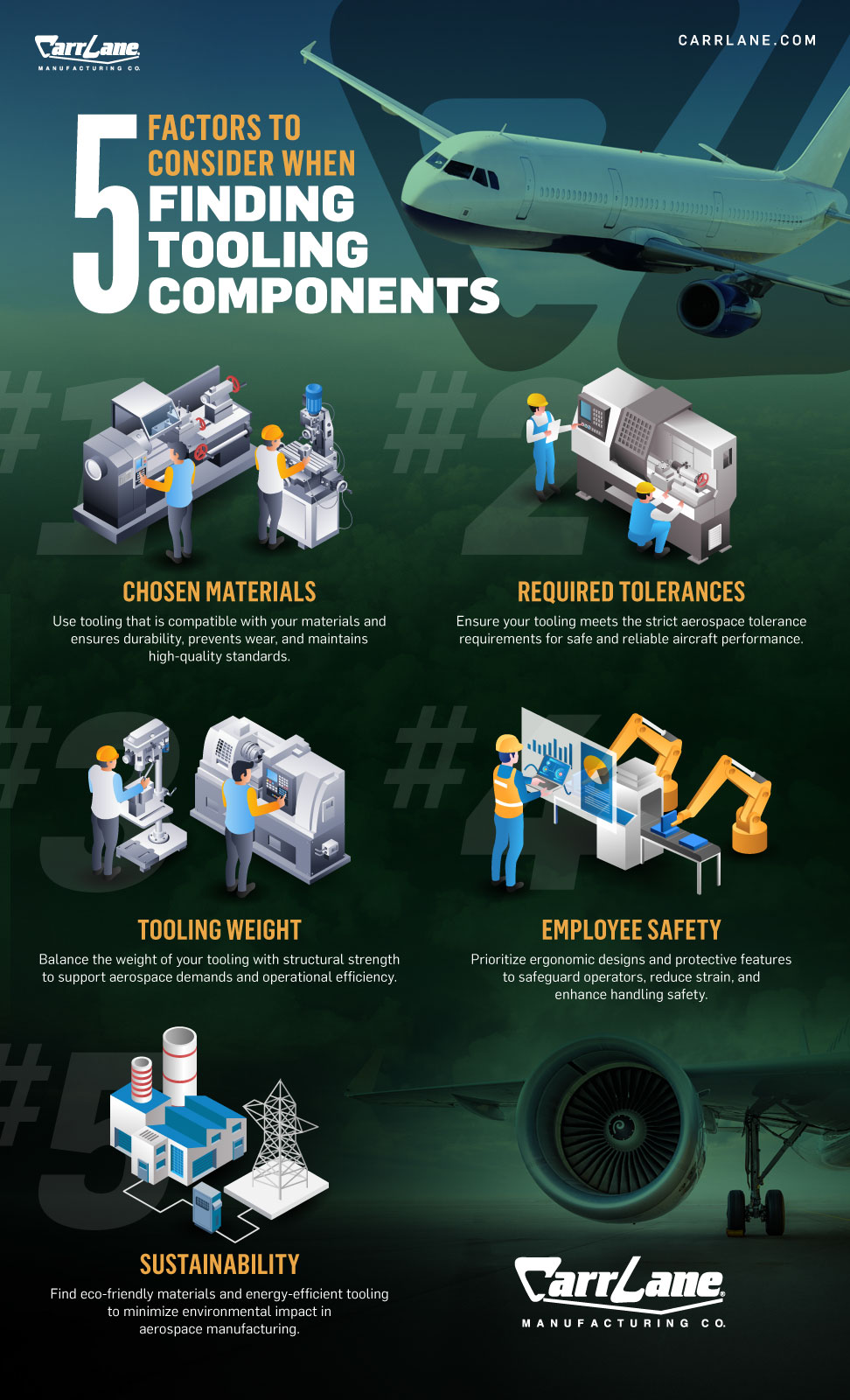

How to Choose Your Tooling Components

Material Compatibility and Durability

Each material has unique properties and requires specific tools and techniques for machining and shaping. Using the wrong tooling material can result in excessive wear, tool failure, and compromised part quality.

Precision and Tolerance Requirements

Precision and tolerance requirements for aerospace tooling are crucial because even the slightest deviations can significantly impact aircraft safety, performance, and reliability.

Some things to consider are the materials you’ll need to use, environmental factors, and dimensional tolerances.

Weight

Aerospace components must be lightweight yet structurally robust to withstand the stresses and forces experienced during operation. Tooling materials must have the right balance between strength, durability, and weight.

The weight of aerospace tooling is all about structural integrity, material selection, manufacturing processes, ergonomics, logistics, and cost.

Safety and Ergonomics

Design tools with ergonomics in mind to minimize physical strain on operators. Consider the design, weight distribution, grip comfort, and adjustable components.

Choose materials that are durable, corrosion-resistant, and non-conductive. You should also select coatings or surface treatments that enhance grip and reduce the risk of slipping. It’s also essential to consider guards and shields to protect operators from moving parts, components, and high-energy systems.

Environmental Concerns

Choose environmentally friendly materials, such as those with a lower carbon footprint, recyclable content, and low toxicity. Use materials that have been certified by environmental standards or organizations.

You’ll also want to consider using components that require less when manufactured and used. Energy-efficient processes contribute to reduced environmental impact.

Types of Aerospace Tooling Components

Carr Lane Mfg. offers a variety of hand tools, cutting tools, assembly tools, and specialized tools for aerospace companies worldwide.

Floating Clamps are an innovative addition to our catalog, designed to provide adjustable clamping that prevents workpiece deformation. These clamps are handy for handling ribbed or flanged castings and larger parts, offering additional support points to reduce machining vibrations.

The DropZero Modular Zero-Point System is another cutting-edge tooling component to streamline manufacturing. It allows the complete machining of a workpiece in a single setup, thus reducing setup time and fixturing costs. This system offers full machining access to five sides of a workpiece. It can easily integrate into existing modular tooling plates and blocks.

Captive Jig Pins are a robust solution for secure, precise alignment, featuring a locking mechanism that positively retains the pin body in a bushing. This type of pin is vital for applications requiring high levels of alignment and positioning accuracy.

Captive Locating Screws featuring a hand knob allow for manual tightening and can be used for locating, clamping, or both. They offer an intuitive, human-centric design while maintaining high standards for precision and reliability.

Headed Slotted Locator Bushings serve to align two holes without binding, featuring a tight tolerance in one direction and complete perpendicular relief to resist axial loads. These are commonly used in situations requiring precise alignment without sacrificing mechanical strength.

ON-SIZE® Bushings are designed for high thermal stability, made from a unique Invar 36 material that minimizes thermal expansion. These bushings are particularly useful in aerospace applications where components are exposed to various temperatures.

Our range of aerospace tooling components serves diverse needs within the industry, from the need for precision in alignment and clamping to the requirements for thermal stability and adaptability in machining setups. Each component has its specialized function, designed to meet the rigorous demands of aerospace applications.

Material Selection for Aerospace Tooling

Material selection is a crucial aspect of aerospace tooling, and Carr Lane Mfg. offers various options to meet diverse needs.

High-strength alloys are often chosen for their exceptional durability and ability to withstand high stress, making them ideal for critical load-bearing components.

Composite materials bring the advantage of being lightweight yet strong, perfect for applications where weight reduction without sacrificing strength is paramount.

Titanium is another favored material known for its excellent strength-to-weight ratio and corrosion resistance. It is ideal for components exposed to harsh environmental conditions.

Steel and other metals remain a reliable choice, offering a balanced mix of durability and cost-effectiveness.

Each material has advantages, enabling engineers to optimize for strength, weight, and resistance to environmental conditions.

Tool Maintenance and Life Cycle Management

Regular maintenance of aerospace equipment is essential to ensure safety, precision, efficiency, compliance, cost savings, and the overall success of aerospace manufacturing.

It’s crucial to visually inspect and functionally test all aerospace equipment thoroughly by trying out different functions. This may involve manual operation, power-on testing, or simulating real-world usage scenarios. Ensure that all safety features are operational and effectively protect the user.

When considering replacing parts, there are a few things you should consider. Look out for wear and tear, performance degradation, regulatory requirements, and the importance of the equipment. While replacing parts can be costly, the safety of the equipment and operators is more important.

Get the Aerospace Parts You Need at Carr Lane Mfg.

Regarding aerospace tooling components, Carr Lane Mfg. is your one-stop shop for quality, precision, and reliability.

Our experienced team is always on hand to provide in-depth information and guidance. From understanding the unique properties of each material we offer to customizing components for specific applications, our experts are ready to assist you in making the best choices for your aerospace projects.

Please get in touch with our team to discover the difference that quality and expertise can make in your aerospace applications.

Contact Us