A leaf jig is a small jig featuring a hinged leaf that carries bushings or other fixture components, through which clamping pressure is applied to a workpiece. While leaf jigs can be used for large and cumbersome workpieces, most designs are limited in size and weight for easy handling. For larger or more cumbersome workpieces, consider using a Hinged Bushing Plate. A leaf jig can be box-like in shape, with four or more sides for drilling holes perpendicular to each side. Leaf jigs with additional feet for operations from multiple sides are often called tumble jigs.

Construction consists of a drill plate or arm (leaf) attached to the jig body with a precisely fitting hinge at one end and a positive positioning clamp at the other end. Similar to universal jigs, each leaf jig must be modified for specific applications. In many leaf jigs, lids swing up to provide easy loading from three sides. Occasionally, a side plate is attached to the lid or base to permit cross drilling or other operations.

The now obsolete Lift-n-C Jig is a type of leaf jig. It gets its name from the way the top plate lifts and opens wide for easy loading (Lift 'n' See). Often used as a drill jig, users must install drill bushings in the top plate and locators in the base to make a finished drill jig. The handle operates a sturdy, durable rack-and-pinion mechanism that lifts the top plate and tilts it back. The handle mounts on either side. This design, unlike most leaf jigs, does not apply positive clamping force to the workpiece.

Channel and Tumble Box Jigs

Channel and tumble box jigs permit drilling into multiple surfaces of a workpiece without relocating the workpiece in the jig. This results in greater accuracy with less handling compared to using several separate jigs in a manual work center. In sophisticated machining operations such jigs are now rarely used. CNC machines, especially those equipped with a workpiece probe, are often much more accurate, even without a jig.

Tumble box jigs often utilized all six sides of the jig, providing a type of manual indexing before the advent of 5-axis machining centers. Before 2000, tumble box jigs were commercially available in various sizes and could be prepared to machine a particular part by adding drill bushings and means to locate and clamp the part. Because of this off-the-shelf availability, designers often chose a tumble box jig over a channel jig when machining only two or three sides of a workpiece. Today, such jigs are rarely, if ever used and thus no longer commercially available.

Hinged Bushing Plates

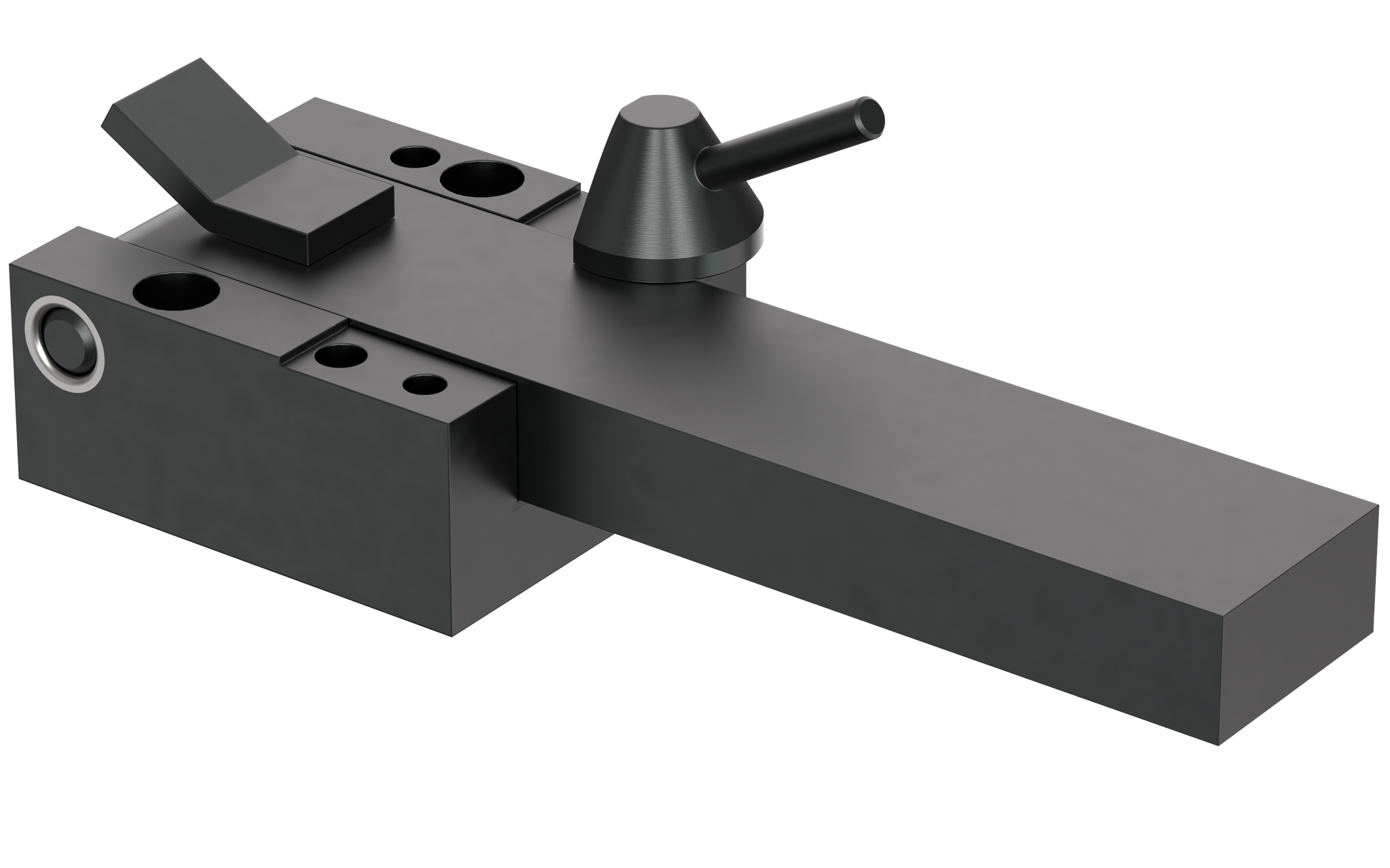

Hinged Bushing Plates, also known as Hinged Bushing Assemblies or Hinge Drops, are a kind of leaf jig. The leaf is the long “arm” that extends from the body of the assembly, which is mounted to the fixture. While often used to both position a workpiece and provide bushings for drilling, they can also be deployed to simply clamp and locate large workpieces. To accommodate these large workpieces, the arm swings 120 degrees to provide easy loading. Hinged Bushing Plates are ideal for large and heavy components in agricultural manufacturing.