Drill bushings are essential components in drill jigs, helping to guide shank-mounted cutting tools to the correct position. In this comprehensive guide, Carr Lane Mfg. provides detailed information about the applications, installation methods, and features of different drill bushings. With this information, you can make data-driven decisions about which drill bushing is best for your operation.

Drill bushings are a significant element in most of today’s drill jigs. They act as precision guiding devices for drills, reamers, taps, counterbores, and similar shank-mounted cutting tools. Drill bushings serve three purposes: locating, guiding, and supporting the cutting tool.

Although they serve mainly as guides for cutting tools, drill bushings also have other uses. They work well in assembly tools, inspection tools, and similar devices that require precise alignment and location of cylindrical parts. Drill bushings are commonly used in jigs and fixtures to ensure precision and repeatability in drilling operations, helping maintain the correct alignment and position of the drill bit as it enters the workpiece. This is essential for producing holes that are accurately sized and properly positioned.

The most common cutting tool for drilling is the twist drill. The design and cutting characteristics of the standard twist drill, although efficient, are not well suited for precision machining. The major reasons are found in the construction of the twist drill. Twist drills have two angled cutting edges. The cutting edges are usually set 118º apart with a lip clearance angle of approximately 12º. The point formed by these angles is called the “chisel edge,” which is usually at 135º to the cutting edges of the drill. This design, although highly efficient for cutting, is not practical for centering the tool.

In addition, the material removed to form the flutes and margins of the drill, combined with the standard back taper, dramatically reduces the contact area between the twist drill and the hole. In most production situations, the drill point is not always precisely centered, leading to oversized holes.

Combined, these conditions result in drilled holes that are off-center, oversized, out of round, out of alignment, and usually not straight. Luckily, supporting the twist drill in a drill bushing can significantly reduce, if not eliminate, most of these problems.

Drill bushings are made from hardened steel or carbide to withstand the wear and tear of the cutting process. They come in various shapes and sizes to accommodate different tool diameters and cutting conditions. Drill bushings are essential in high-volume production settings where precision and efficiency are vital, improving the quality of the finished product and extending the life of cutting tools by reducing wear.

Drill bushings come in various types and styles, each designed to work best with specific manufacturing applications. The three general categories of drill bushings available are permanent, renewable, and air-feed-drill bushings.

Figure 10-1 shows that drill bushings are identified by letters and numbers. These letters and numbers describe the basic form and specific sizes of each bushing in a format established by the American National Standards Institute (ANSI). This format consists of one to four letters to identify the bushing type, an OD size of 64ths of an inch, a length of 16ths of an inch, and the ID of the bushing stated to four decimal positions.

Figure 10-1. Drill bushings are specified by ANSI letter-and-number designations, identifying the bushing type and the specific dimensions.

Permanent Drill Bushings

As their name suggests, permanent bushings are designed to be installed permanently into jigs or fixtures for limited-production applications where bushings are not regularly changed during the service life of the workholder. These bushings are manufactured to tight tolerances, ensuring consistent and accurate hole sizes and locations over many cycles.

Permanent bushings are pressed directly into the jig plate or cast in place. Since these bushings are permanently installed, repeated replacement would cause the mounting hole to wear and reduce the accuracy and soundness of the installation. They are available in many shapes, sizes, and varieties to accommodate operational requirements.

Press-Fit Drill Bushings

Press-fit bushings are the most common and least expensive permanent bushing. These bushings are identified by the letter P (or PC when the bushing is carbide). The headless design allows the bushings to be mounted close together and flush with the top of the jig plate. This design, however, offers less resistance to heavy axial loads.

Figure 10-2. Plain press-fit bushings are the most popular and least expensive drill bushings for permanent installations.

Press-fit bushings are designed for one-step operations, such as drilling or reaming. They are securely installed by press fitting or pressing the bushing directly into the jig plate. They are held in place by the force of the press fit. Figure 10-3 shows recommended hole sizes for press-fit bushings.

Figure 10-3. Recommended hole sizes for press-fit bushings in unhardened steel or cast iron jig plates.

Head Press-Fit Bushings

Head press-fit bushings are like the press-fit bushing in design and application but are made with a head for added axial support. Head press-fit bushings are designed for applications where heavy axial loads might push a press-fit bushing through the mounting hole. Head press-fit bushings are types H or HC (carbide) and can be mounted with the head exposed or counterbored (if the bushing must be flush with the top of the jig plate).

Figure 10-4. Head-type press-fit bushings have a head to resist heavy axial loads.

When the jig plate is counterbored, only the body diameter of the bushing provides the location, and only this diameter needs to be reamed. The counterbored area provides clearance for the head and should not be a precision fit. Figure 10-5 shows standard head diameters. The length of the bushing is measured from the underside of the head to the exit end of the bushing.

Figure 10-5. Dimensions of head-type press-fit bushings.

Serrated Press-Fit Bushings

Serrated press-fit bushings, type SP, are a variation of press-fit drill bushings used for applications where a hardened drill bushing is mounted in a soft jig plate. The bushings have an external mounting surface with a precision-ground diameter and a serrated or straight-knurled area. The ground portion aligns the bushing in the mounting hole in the same way a press-fit bushing does. The serrations prevent any rotational movement from high torque loads by enhancing the grip between the bushing and the material of the jig plate. The serrations also resist axial loads that could push the bushing through the jig plate. These bushings are well suited for jig plates made from aluminum, magnesium, Masonite, wood, or similar soft materials.

Figure 10-6. Serrated press-fit bushings have serrations on top to prevent rotation in soft materials such as aluminum.

Serrata Groove Bushings

Serrata groove bushings, type SG, are similar to the serrated press-fit bushing, but instead of combining a precision diameter and serrations, they are serrated over their entire length. The serrations and grooves cut around the circumference of these bushings make them ideal for pressed-in or cast-in-place applications. These bushings offer high torque resistance, but due to their straight-knurled mounting surface, they have a reduced resistance to axial loads. Similarly, since the circumference of these bushings is serrated and not ground, the internal diameter must be used to align the bushing for cast-in-place applications.

Figure 10-7. Serrata groove bushings have full-length straight serrations for cast-in-place or potted installations.

Diamond Groove Bushings

Diamond-groove bushings, type DG, are another form of bushing for cast-in-place applications. As shown in Figure 10-8, these bushings resemble the serrata groove bushing, but they have a diamond pattern knurl rather than a straight pattern knurl on the circumference. The diamond knurl offers high resistance to both rotational and axial forces. Like the serrata-groove bushings, the circumference of the diamond-groove bushings is knurled and not ground, so the internal diameter must be used to align the bushing for cast-in-place applications.

Diamond groove bushings should not be used for press-fit applications. Straight serrated bushings are ideal for press-fit applications because when pressed into the jig plate, the material displaced by the points of the knurl is moved into the area between the points. On the other hand, a diamond-pattern knurl will cut the materials and broach the hole larger.

For cast-in-place applications, the bushings are mounted in holes that have a larger diameter. The space between the outer surface of the bushing and the inside of the hole is filled either with epoxy resin or a low-melting-point alloy.

Figure 10-8. Diamond groove bushings have a diamond-knurled OD for cast-in-place or potted installations subject to heavy axial loads.

Template Bushings

Template bushings, type TB, are designed for thin jig plates. Also known as template guide bushings or guide bushings, these bushings precisely follow the contours of a template or pattern. They permit larger diameter tools to be used with a thin jig plate. Rather than using a thicker jig plate customarily required to support larger diameter drills, template bushings provide the necessary drill support in jig plates from 1/16” to 3/8” thick. This reduces both the cost and the weight of the jig plate.

Figure 10-9. Template bushings are for thin template jig plates 1/16” to 3/8” thick.

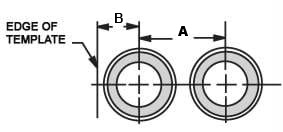

Template bushings are installed with an installation tool. When locating template bushings, follow the minimum edge distances and hole spacings shown in Figure 10-10(a). Once properly located, the mounting hole is drilled and reamed .001” to .003” larger than the mounting diameter of the bushing. The hole is countersunk on the workpiece side, allowing the bushing to sit .015” below the surface, Figure 10-10(b). The bushing is then inserted and pressed into the hole. Here are a few best practices for installing template bushings:

1. Laying Out Holes

When laying out the holes, observe the minimum hole spacing and edge distance listed below:

| Bushing OD |

A Minimum |

B Minimum |

| 3/8 |

.60 |

.250 |

| 1/2 |

.73 |

.312 |

| 3/4 |

.98 |

.438 |

2. Creating a Countersink for a Ream Hole

Ream the hole .001 to .003 larger than the bushing’s outer diameter. Countersink the reamed hole to allow the bushing to sit .015 below flush with the surface. For the best results, use a piloted countersink tool so that the countersink is concentric and free of chatter marks.

3. Installing the Retainer Ring

The retaining ring is mounted with the installation tool tapped for mounting on a rivet gun or other impact tool. When mounting the retaining ring, ensure the top of the ring is within +.005”/-.10” of the top of the groove in the bushing, as shown in Figure 10-10(c), before using the installation tool. The serrations on the bushing circumference prevent rotational movement. The retaining ring locks the bushing in the jig plate and restricts axial movement.

Figure 10-10. Installation procedure for template bushings.

Circuit-Board Bushings

Circuit-board bushings are designed to protect and reinforce the holes on a printed circuit board (PCB) during and after component insertion. These bushings fit precisely within drilled holes, providing a snug fit for component leads and enhancing the durability of the connection points against mechanical stress or movement. Circuit-board bushings are meant to accommodate the large shanks of circuit-board drills. They are suitable for diverse applications in electronics manufacturing.

Figure 10-11. Circuit-board bushing variations.

Liner Bushings

Liner bushings, type L, are permanent bushings that resemble press-fit bushings but are larger. Liner bushings are used with renewable-style bushings to provide a hardened, wear-resistant hole in an otherwise soft jig plate. The close sliding fit between the renewable bushing and the liner bushing permits the bushing to be changed repeatedly over long production runs with no loss of positional accuracy. The headless design of liner bushings allows them to be mounted close together and flush with the top of the jig plate. Still, like press-fit bushings, they offer less resistance to heavy axial loads.

Figure 10-12. Liners are permanent bushings used to hold and locate renewable drill bushings.

Head Liner Bushings

Head liner bushings, type HL, are like the liner bushing in design and application, but they are made with a head. Head liner bushings, like head-press-fit bushings, are designed for applications where heavy axial loads might push a press-fit bushing through the mounting hole. These bushings can be mounted with the head exposed or counterbored. When the jig plate is counterbored for mounting, only the body diameter of the bushing provides the location, and only this diameter needs to be reamed. The counterbored area provides clearance for the head and should not be a precision fit. Figure 10-13 shows standard head diameters, with the bushing length measured from the top to bottom of the bushing and including the height of the head.

Figure 10-13. Dimensions of head-type liner bushings.

Renewable Drill Bushings

Renewable bushings are one of the three general categories of bushings designed for applications where the bushings must be changed regularly during the service life of the workholder. Bushing changes occur when bushings wear out, or multiple operations are performed in the same hole. With multiple operations, two or more drill bushings produce the desired hole. The two principal forms of bushings for renewable installations are renewable drill bushings and liner bushings. The drill bushing locates and supports the cutting tool, while the liner bushing locates and supports the drill bushing. Both drill bushings and liner bushings for renewable arrangements are available in several styles.

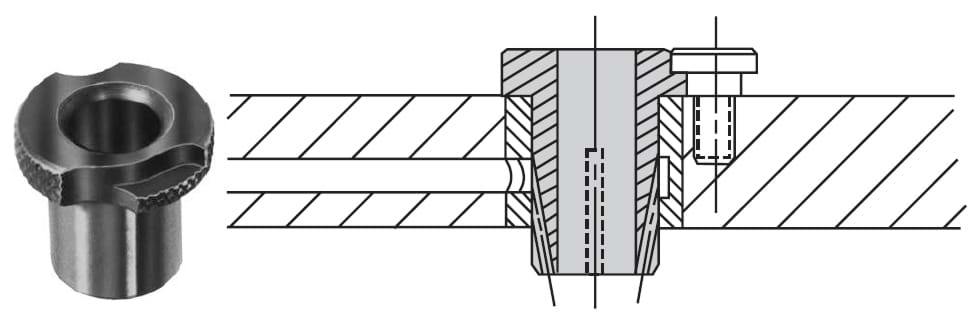

Slip/Fixed Renewable Bushings

Slip/fixed renewable bushings, types SF and SFC (carbide), are the most common form of renewable bushings. This renewable bushing replaces the older and obsolete slip renewable, type S, and fixed renewable, type F, bushings, combining the slip and fixed locking arrangements in a single bushing. One part of the bushing setup is fixed, serving as a holder or liner, while the other part, the actual bushing, can slip into and out of this holder.

Figure 10-14. Slip/fixed renewable bushings are replaceable drill bushings used in high-volume production.

Slip/fixed renewable bushings are typically employed in long production runs where bushing changes are needed. These bushings can be installed in either a fixed-renewable or slip-renewable configuration by rotating the bushing. The fixed-renewable installation is intended for single-step applications such as drilling or reaming, and the bushings are changed only when they wear down. These bushings are held with a lockscrew or round clamp, which keeps the bushing in place and prevents movement during the machining cycle. When the bushing must be replaced, the clamp is removed, and the bushing changed. The clamp is then reinstalled to hold the bushing securely.

Slip-renewable installations are convenient for applications when multiple operations are performed in the same hole. One example is drilling and reaming the same hole. The first slip-renewable bushing is installed, and the hole is drilled. The drilling bushing is removed before the reaming bushing is installed, and the hole is reamed to size.

Figure 10-15. The slip/fixed renewable bushing can be installed as either fixed-renewable or slip-renewable by simply rotating the bushing.

The slip-renewable side allows rapid changeover. The bushing is rotated clockwise to lock it in place and rotated counterclockwise for removal. A cutout at the end of the recess makes the bushing easy to remove and replace. This design ensures that the drill rotation will not allow the bushing to back out of the hole. Although slip/fixed renewable bushings are usually installed in a liner bushing, they can also be installed directly in the jig plate. Figure 10-16 shows the recommended hole sizes for installing slip/fixed renewable bushings without a liner bushing.

Figure 10-16. Recommended hole sizes for installing slip/fixed renewable bushings without a liner bushing.

Drill Bushings for Counterbores

The most effective contact area between the bushing ID and the cutting tool is approximately 1 ½ times the diameter of the cutting tool. This added bearing surface can create more resistance to the drill and cause chips to build up inside the bushing, causing premature wear or breaking the drill entirely. For these reasons, standard drill bushings with a length over this approximate 1 ½ size will be counterbored at the top. This counterbored portion still provides adequate drill support while alleviating possible chip buildup issues and drill breakage. The counterbore data chart in Figure 10-15 indicates which bushing lengths are counterbored and which are not. These extended bushings may be ordered as “no counterbore” at an extra charge.

Figure 10-17. Long bushings for small drill sizes are slightly counterbored to prevent binding and heat buildup due to excessive bearing length.

Lockscrews and Clamps

Renewable bushings are typically held in the jig plate with a lockscrew or a clamp. The lockscrew or clamp radially locates the bushing in the liner and holds the bushing in place. The lockscrew, shown in Figure 10-18(a), is the most common locking device. These screws generally mount the bushings on either their slip-renewable or fixed-renewable sides. They are made with a shoulder under the head. For mounting bushings on their slip-renewable side, the shoulder provides the necessary clearance to rotate the bushing for installation and removal. When mounted on the fixed-renewable side, the underside of the head securely holds the bushing in place.

The lockscrew locating jig, seen in Figure 10-18(b), locates the lockscrews to the renewable bushing. As demonstrated in Figure 10-18(c), the lockscrew locating jig is positioned against the bushing and struck with a hammer to mark the location of the lockscrew.

Figure 10-18. Lockscrews are the most common holding device for renewable bushings. The center punch shown is a multi-purpose locating jig for most lockscrews and clamps.

A round end clamp, shown in Figure 10-19(a), can also be used for mounting bushings on either their slip-renewable or fixed-renewable sides. This clamp comes in two heights for bushing installations with either a recessed or projected liner, as seen in Figure 10-19(b).

(A)

(A)  (B)

(B)

Figure 10-19. The round-end clamp is a heavy-duty alternative to lockscrews.

The round clamp, not to be confused with the round end clamp, is a bushing clamp designed to hold bushings on their fixed-renewable side. As shown in Figure 10-20, round clamps are held in place with a socket-head cap screw. The lockscrew locating jig can also be used to install these clamps.

Figure 10-20. The round clamp is used to clamp bushings tightly on their fixed-renewable side.

The flat clamp, shown in Figure 10-21(a), is another bushing clamp. These clamps are used for the older styles of fixed-renewable bushings with a flat-milled clamping area. Like the round end clamp, the flat clamp is made in two heights for bushing installation with either a recessed or projected liner, as illustrated in Figure 10-21(b).

Figure 10-21. The flat clamp is used for fixed-renewable bushings that have a flat-milled clamping area.

Locking Liner Bushings

The locking liner bushing, type UL, is a unique design for slip-renewable bushing installations. As shown, the bushing combines both liner and locking components in a single unit. The basic design of this bushing is like a head liner, but it has a unique locking tab that eliminates the need for a lockscrew. Locking liner bushings are slightly more expensive than the head liner bushing/lockscrew unit they replace. However, the reduced installation time does not offset any additional cost. Note: these liners can only be used on the slip-renewable side.

Figure 10-22. Locking liner bushings include a special locking tab that eliminates the need for a lockscrew. These liners can only be used for slip-renewable applications and are not fixed.

Diamond-Knurled Locking Liner Bushing

The diamond-knurled locking liner bushing, type ULD, is a variation of the locking liner. These bushings are a form of liner bushing for cast-in-place applications. They combine both the liner and the locking device into a single unit, but the diamond-knurled locking liners have a diamond-pattern knurl on their circumference. The knurl offers high resistance to both rotational and axial forces. Like the other knurled bushings, the circumference of these liner bushings is not ground, so the internal diameter must be used to align the bushing for cast-in-place applications.

Figure 10-23. Diamond-knurl locking liner bushings are cast-in-place or potted.

EZ-Cast Liner Bushings

EZ-Cast liner bushings, type EZ, are another form of cast-in-place liner bushing. However, unlike the diamond-knurled locking liners, these bushings have an integral lockscrew. They can mount either side of slip/fixed renewable bushings.

The headless design of these liner bushings permits them to be mounted flush with the top of the jig plate, while the diamond-pattern knurl offers high resistance to rotational and axial forces. Like other knurled bushings, the mounting surface of these bushings is not ground, so the internal diameter must be used to align the bushing accurately.

Figure 10-24. EZ-Cast liner bushings are cast-in-place liners that can be used for either slip- or fixed-renewable applications.

Gun-Drill Bushings

Gun-drill bushings are specialty bushings for deep-hole drilling machines. The type of gun-drilling machine determines the type of bushing.

Gun-drill bushings are like slip/fixed renewable bushings in appearance and application but have the drill-bearing area at the head end of the bushing. Depending on the gun-drilling machine, these bushings are either one-piece or two-piece units.

Figure 10-25. Gun-drill bushings are specially designed for gun-drilling machines (deep-hole drilling).

The GD-type gun-drill bushing is a one-piece bushing. Figure 10-26 shows that a third letter is added to the GD designation. This letter matches the bushing to a specific type of gun-drilling machine. The GDL (liner) and GDI (insert) bushings are two-piece units. As shown in Figure 10-27, these bushings are used together.

Figure 10-26. Variations of one-piece gun-drill bushings.

Figure 10-27. The gun-drill liner and gun-drill insert bushings are used together.

Air-Feed Drill Bushings

Air-feed drill bushings are special-purpose bushings designed for various commercial self-feeding air-feed drills, tappers, and back-spot facers. These drill bushings, called “shanks,” are part of a complete system that includes the shanks, collars, and mounting devices. The shanks and collars are available either individually or as assembled units. When assembled, the unit is called an adaptor-tip assembly.

Like standard bushings, the shanks are made with an internal diameter sized to fit the cutting-tool diameter and an external diameter sized to fit the jig-mounted liner bushing. The collar is designed to mount the tip assembly to the self-feeding drill motor and hold the complete unit in the jig-mounted liner bushing. Figure 10-28 shows that the tip assembly is inverted in the liner and turned counterclockwise 30º to lock the units together. Figure 10-29 shows the various mounting options for the jig-mounted liner bushings.

Figure 10-28. Air-feed drills are mounted by inserting the adaptor tip into a locking liner.

Figure 10-29. Liner-mounting options for air-feed-drill bushings.

The two primary forms of air-feed bushings are standard and coolant-type air-feed drills. Standard air-feed bushings, Figure 10-30, have a tip assembly from individual shank and collar units. The collar attaches the unit to the air–feed–drill's nosepiece directly or through an optional reducer. The shank can have a plain end or a contour-nose design.

Figure 10-30. The nose assembly of a standard air-feed drill.

The contour-nose shank is a modified standard for applications where curved or sloped surfaces are drilled. As shown in Figure 10-31, the contour-nose shank has a dual-angle angular relief of 8º and 45º on the end of the shank.

Figure 10-31. The contour-nose shank is modified for drilling curved or sloped surfaces.

Coolant-type air-feed drills use coolant-inducing bushings, essentially the same as standard air-feed bushings except for adding drilled passages in each element. This forces coolant through the assembly to the cutting tool. The coolant-type air-feed drill’s nosepiece is also different, as shown, to fit the connector for the coolant hose.

Figure 10-32. Coolant-induced bushings are similar to standard air-feed bushings but have holes in each element to force coolant into the cutting tool.

In addition to the standard bushing variations, a range of optional features are also available for specific drilling situations. These optional features increase the versatility of the bushings and are helpful in several ways.

Chip-Breaker

Chip-breaker bushings, type CH, are similar to the SF renewable-type bushings. These bushings, however, have a series of specially designed notches on the drill-exit end of the bushing to break up chips created when tough or stringy materials are drilled.

Breaking up the chips reduces friction and heat buildup while reducing wear on the drill-exit end of the bushing, minimizing any chance of damage to either the bushing or the workpiece. Chip breakers like P and H bushings are also available for other bushing types.

Figure 10-33. Chip-breaker bushings have specially designed notches on the drill-exit end for breaking chips.

Directed Coolant Passages

Directed-coolant bushings, shown in Figure 10-34 are also like the SF renewable bushings. Directed-coolant bushings, type DC, come with coolant passages machined into the bushings to direct the coolant flow to the cutting area. This design both cools the cutting tool and washes away the accumulated chips.

Directed coolant bushings can be mounted in either DCL (liner) or DCHL (head liner) bushings. These special liner bushings have a unique design that directs the coolant flow from a drilled manifold passage through the liner to the holes in the bushing wall.

Figure 10-34. Directed-coolant bushings have drilled passages to direct coolant to the cutting area.

Figure 10-35. Directed-coolant liners are used with directed-coolant bushings.

Oil Groove Bushings

Oil groove bushings ensure adequate cooling and lubrication of the cutting tool. This bushing style is well suited for drilling hardened steel, requiring a constant supply of cutting oil. They are available in most bushing styles, including P, H, and SF renewable bushings, with grooves specially designed as passageways in the internal wall of the bushing.

Oil-groove bushings are made with either an oil hole, an oil hole and an external groove, or without an oil hole, as illustrated in Figure 10-36. The bushings with oil holes direct the oil flow from a drilled manifold passage. Bushings without an oil-feed hole use gravity to feed oil to the cutting tool through the head end of the bushing. There are 25 groove patterns to fit virtually any requirement, with end wipers also available to keep out dirt and chips. These wipers are for oil-groove patterns that do not break out at the wiper end.

Figure 10-36. There are three general options for supplying fluid to the internal grooves.

Figure 10-37. Oil-groove bushings are available in 25 different groove styles.

Angled Exit Ends

Bushings should always be positioned to offer maximum support for the cutting tool. Occasionally, with odd-shaped surfaces, this is not possible with standard bushings. In these cases, the exit end of the bushing must be modified or altered to match the specific shape of the workpiece surface.

Figure 10-38 illustrates bushings with angled exit ends are available for such conditions. Altering the shape of the exit end of the bushing affords the best support while preventing any lateral movement or wandering of the cutting tool. Although almost any cutting tool of any size can move off the desired center position if improperly supported, this is especially true with smaller-diameter cutting tools.

Figure 10-38. Angled-exit-end bushings are sometimes required for drilling curved or sloped surfaces.

Ground Flats

Ground flats are typically specified for bushings that must be positioned close to each other in the jig plate, as they allow standard bushings to be positioned very close together with a simple alteration. Although almost any bushing can use ground flats, they are especially appropriate for headed bushings, as shown in Figure 10-39.

Figure 10-39. Ground flats can be used to position bushings close together.

Thinwall Bushings

Thinwall bushings, as their name implies, are drill bushings made with a very thin wall, as illustrated in Figure 10-40. These bushings are also used for applications where holes are close together.

One note of caution: Since the wall thickness is relatively thin, these bushings will tend to follow the shape of the mounting hole. For this reason, the geometry of the mounting hole is fundamental to the accuracy of the installation.

Figure 10-40. Thinwall bushings can also be used to position bushings close together.

Standard drill bushings are made of 1144 Stressproof steel. These are hardened to an RC 62-64 inside diameter hardness. Other materials, such as 52100 steel, 300-series stainless steel, 400-series stainless steel, A2 tool steel, D2 tool steel, D3 tool steel, M2 tool steel, tungsten carbide, and bronze, are also available for special situations.

Brass and bronze are ideal options for drilling bushing as a bearing surface. Brass is softer than bronze but typically contains higher amounts of lead, providing lubrication to the bearing surface and reducing wear. Bronze is lead-free and softer than the steel part that typically passes through the bushing. Because of this, wear occurs in the bushing, not the mating part, like most brass, leaded materials cannot be exported to the European Union.

Tungsten carbide is also frequently used as a bearing surface to avoid wear in the bushing. This rigid material will result in wear on the part that interacts with the bushing, making it an ideal choice if it is inaccessible for service and maintenance or is subjected to high temperatures. Headed tungsten carbide drill bushings are made of two pieces: a steelhead pressed onto the carbide body. Because special-size carbide bushings require a mold to be made before sintering and finishing, lead times for special carbide bushings are typically 16 weeks.

In addition to the wide range of standard bushing sizes, virtually any combinations of inside diameter, outside diameter, length, head size, head style, or special tolerances are readily available as specials. These special bushings can be customized to fit any special machining situation or need.

Standard special bushings include:

- Very small ID Bushings, below 0.001” or 0.025mm

- Very Large ID Bushings, over 2.00” or 50mm

- Bushings with a mixture of Inch and Metric dimensions

- ID or OD Tolerance of 0.0001” or 0.0025mm

- Concentricity of 0.0001” or 0.0025mm

In some cases, special bushings may not be able to be specified using the ANSI Standard. For example, a drill bushing with a length of 7/16” cannot be specified using the ANSI standard. When requesting a quote for special Carr Lane Mfg. bushings, please specify the fractional or decimal equivalent in the standard location for that value. An example of the 7/16” length from above could be P-16-0.4375-.2500 because the second numerical value notes the bushing length. The same may also be noted as P-16-7/16-.2500. Please use our ANSI Standard Part Numbers resource to determine a part number. If an item is not configurable, don't hesitate to contact us to discuss your needs and application.

Drill bushings must be installed appropriately to do their job. The installation starts with a careful design process that matches the bushing type and size with the required operations. This process also involves selecting the correct jig plate thickness and establishing the proper mounting clearance between the bushing and workpiece. When installing drill bushings, we recommend following these best practices:

Use Jig Plates for Placement & Support

“Jig plate” is the term used to identify the parts of a jig that hold and support the drill bushings, and the thickness of the jig plate plays a vital role in drill bushing installation. The sizes of the bushings required usually determine the jig plate thickness.

Generally, bushings should only be long enough to guide and support the cutting tool properly. As shown in Figure 10-41, the thickness of the jig plate should generally be one to two times the tool diameter. This thickness provides adequate support for the cutting tool while keeping the jig plate as light as possible. The largest tool diameter usually determines jig plate thickness when several different drill sizes are used.

Figure 10-41. Jig plate thickness should be 1 to 2 times the tool diameter.

Measure Chip Clearance Requirements

Chip clearance is another factor that must be carefully thought out before selecting and installing drill bushings. Chip clearance is the distance between the end of the bushing and the surface to be machined. As a rule, materials or operations that produce large, stringy chips typically require greater clearance. In contrast, those that produce small chips need less.

In most cases, installations with little or no clearance will position the tool more accurately but tend to clog with chips. Also, when a bushing is positioned against the workpiece, the actual bearing area of the drill in the bushing is reduced by the length of the drill point. Too large a clearance, on the other hand, while less likely to clog, can also increase the chance of inaccurate positioning.

Figure 10-42 shows that the recommended clearance for general-purpose drilling is ½ to 1 ½ times the tool diameter. This clearance between the bushing and workpiece reduces chip interference. An operation such as reaming, which produces smaller chips and requires greater positional accuracy, should generally have a clearance of approximately ¼ to ½ the tool diameter. In these situations, the smaller chips are less of a problem and require reduced clearance to ensure the necessary accuracy.

Figure 10-42. Chip clearance should be ½ to 1 ½ times the tool diameter for drilling and ¼ to ½ times the tool diameter for reaming.

When drilling and reaming are performed in the same location with a renewable bushing, two different bushing clearances can be used. A bushing arrangement shown in Figure 10-43, slip/fixed renewable bushings with two different lengths, meets both clearance requirements. The shorter bushing is used for drilling, while the longer bushing is used for reaming.

Figure 10-43. Different-length slip-renewable bushings can be used when holes are drilled and reamed.

Prepare an Installation Hole

The first considerations in drill-bushing installation are the size and geometry of the mounting holes. All mounting holes must be perfectly round, so they should be jig-bored or reamed to ensure the correct roundness. Ordinary twist drills should not be used to finish mounting holes because they rarely cut a truly round or exact-size hole. The hole size is critical if the bushing is to perform correctly.

The ideal interference, or press fit, is .0005” - .0008” for liners and headless press-fit bushings and .0003” - .0005” for head-type press-fit bushings. A greater interference fit can cause problems by distorting the bushing or deforming the jig plate. Less than the recommended interference fit can result in a loose-fitting bushing that spins when a load is applied.

Other factors to consider when determining the size of a mounting hole are:

- Head-type bushings require less interference to resist drilling thrust.

- Longer bushings in thicker jig plates require less interference.

- Thinwall bushings are more prone to distortion than typical bushings.

- Less-ductile jig-plate materials require less interference.

Utilize the Proper Tools & Procedures for Installation

An arbor press is preferred for drill bushing installation, as illustrated in Figure 10-44(a). Using an arbor press permits constant and even pressure. However, if an arbor press is unavailable and the bushing diameter is large enough, a drawbolt and washer can also be used, as shown in Figure10-44(b). If the only tool available is a hammer, do not strike the bushing directly, as this could fracture the bushing. Instead, use a soft-metal punch to cushion the hammer blows.

Figure 10-44. Two methods for properly installing press-fit bushings.

To prevent damage to the bushing or mounting hole, coat both the inside surface of the mounting hole and the outside of the bushing with a lubricating compound. This makes the installation easier and reduces any scoring or galling between the mating surfaces. Finally, always install the bushing with the ground lead entering the hole first. This lead helps align and position the bushing for installation.

Use Unground Bushings for Oversized Holes

Each style of press-fit bushing is also available with an unground outside diameter. These are intended for customized applications in mounting holes that are worn or otherwise oversized. Unground bushings are specified by adding the letter “U” in the standard bushing designation, e.g., HU-20-16-.1250.

The bushing size and style determine the amount of grinding stock left, but the range is from .005” to .020”. When grinding the bushings to a specific size, a mandrel should be used to ensure the required concentricity of the inside and outside diameters.

Find the Perfect Drill Bushings for Your Application at Carr Lane Mfg.

Regardless of your machining process or application, Carr Lane Mfg. offers a wide range of drill bushings across all three categories: permanent, renewable, and air-feed. If you can’t find the bushing you need after browsing our product catalog, our experts can help you create a special bushing to fit your application best.

To discuss your needs and find the best solutions for your operation, contact a Carr Lane Mfg. expert today.